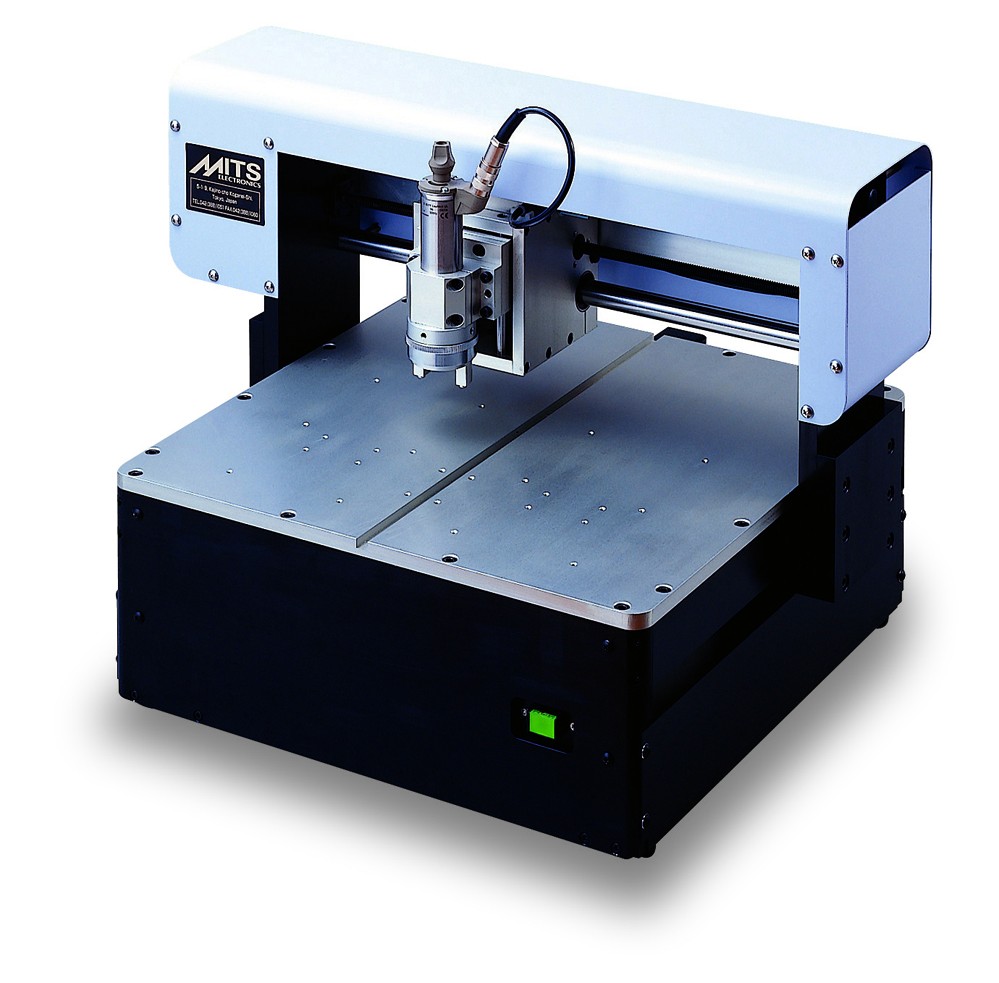

The FP-21T

The FP-21T

The FP-21T is a very sturdy system designed for “Processing Accuracy”. With various options and versatile software functions, FP-21T is suitable not only for typical PCB prototyping but also for processing thin materials, various hard and soft materials, 2.5 Dimensional work, additional work and other works.

Non-Contact Milling Head

As the board is pressured by air pressure, it leaves no undesirable traces on the board surface. Suitable for milling the soft substrate board such as teflon circuit board.

Manual Tool Change

Tool change can be done without any complicated action such as thread fastening.

Standard camera monitoring system.

You can easily adjust the right position while viewing display. Camera is also used for making double sided boards. The MITS Software has a built in function for aligning the bottom side of the board with high precision.

(Maximum useful magnification depends on the size of the screen).

Web Video

The FP-21T Specifications

| Model | FP-21T |

|---|---|

| Minimum milling width (mm) | 0.1 (4 mil) |

| Working area (X/Y/Z) (mm) | 350 x 250 x 25*8 (14″ x 10″ x 1″) |

| Table size (X/Y) (mm) | 460 x 450 (18″ x 18″) |

| Control axis | X, Y, Z |

| Control motor | 5 Phase Stepper Motor |

| Resolution (µm) *3 | 4 (0.16 mil) |

| Maximum Travel Speed (mm/sec.) *1 | 80 (3.15″) |

| Spindle speed min-1 (rpm) Spindle motor | 5,000 – 40,000 (model 40) 5,000 – 60,000 (model 60) 5,000 – 100,000 (model 100) HF Spindle |

| Drilling (mm) | 0.2 – 3.175 (8 – 125 mil) |

| Maximum drilling cycle (cycles/min.) *2 | 80 |

| Maximum drilling stroke (mm) | 30 (1.18″) |

| Tool change | Manual / Single step tool change |

| Milling method (Absolute) | Manual switching |

| Milling method (Incremental) | Yes |

| Power consumption | 100 – 240 V, 50-60 Hz, 200VA |

| Machine dimensions W x D x H (mm) | 620 x 505 x 420 (24″ x 20″ x 17″) |

| Machine weight (kg) | Approx. 42 (93 lbs) |

| Interface | One USB or one RS-232C port |

| Standard equipment | Software: EASY CAD, Conversion + CAM Fiducial positioning camera 30x Vacuum table (VT-ABS) Dust proof, Acoustic cabinet Tool protrusion equipment |

| Options and accessories | Cabinet (requires assembly) Vacuum table Ring-setter / Precision ring-setter (manual) Drilling ring Microscope 100x Software: Vacuum cleaner |

| Starter kit (Sold Separately) | Connecting Cable (RS232C / USB) Magnifying glass 10x Extension hose for Vacuum cleaner Tools: End mills - Drill bits - Router bits Tape Lubricant Scoring Pad |

Join The Most Satisfied MITS Users!